ThrustMe and the von Karman Institute expand space testing capabilities with a new facility integrating the LTA100 particle flow generator

Posted on 2 March, 2023

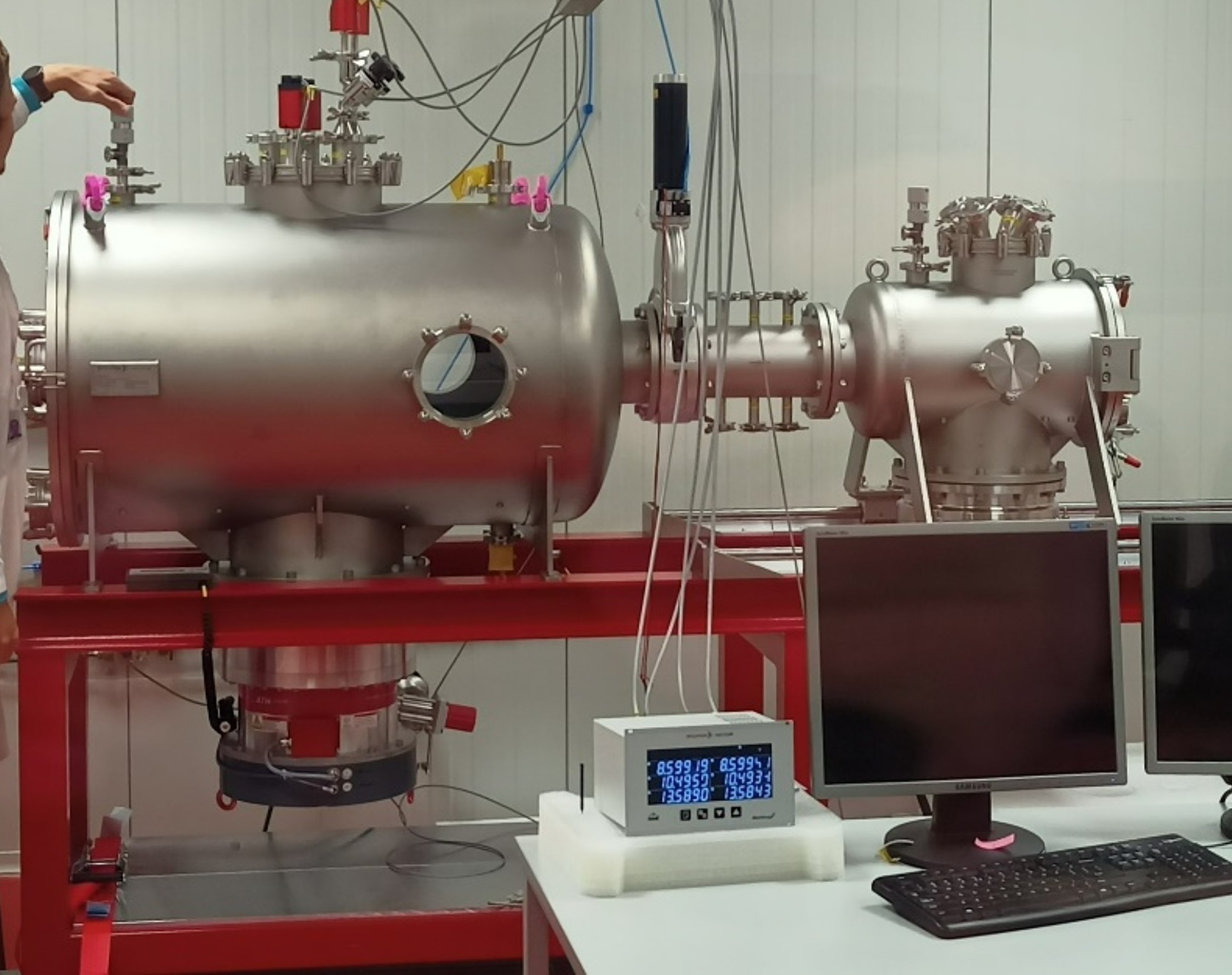

ThrustMe and the von Karman Institute for Fluid Dynamics (VKI), with the support of the European Space Agency, are excited to announce the success of the acceptance campaign of the new DRAG-ON facility, “Dual-chamber for RArefied Gases and ON-ground testing” which integrates the LTA100 particle generator. This revolutionary device, developed by ThrustMe, expands the testing capabilities of the von Karman Institute and makes it possible to reproduce the environment of the ionosphere and upper atmosphere for testing new propulsion concepts, as well as qualifying space hardware ahead of launch. With this new facility, the VKI can now simulate the high speed, low density flow that a spacecraft would encounter in Earth Orbit at an altitude of approximately 200 km - intermediate between the "Kármán line" (100 km) and the orbit of the International Space Station (400 km), opening a variety of opportunities for developing air-breathing propulsion systems.

contact@thrustme.fr

ThrustMe : +33 6 31 90 65 50

christelle.debeer@vki.ac.be

VKI : +32 4 75 75 14 75

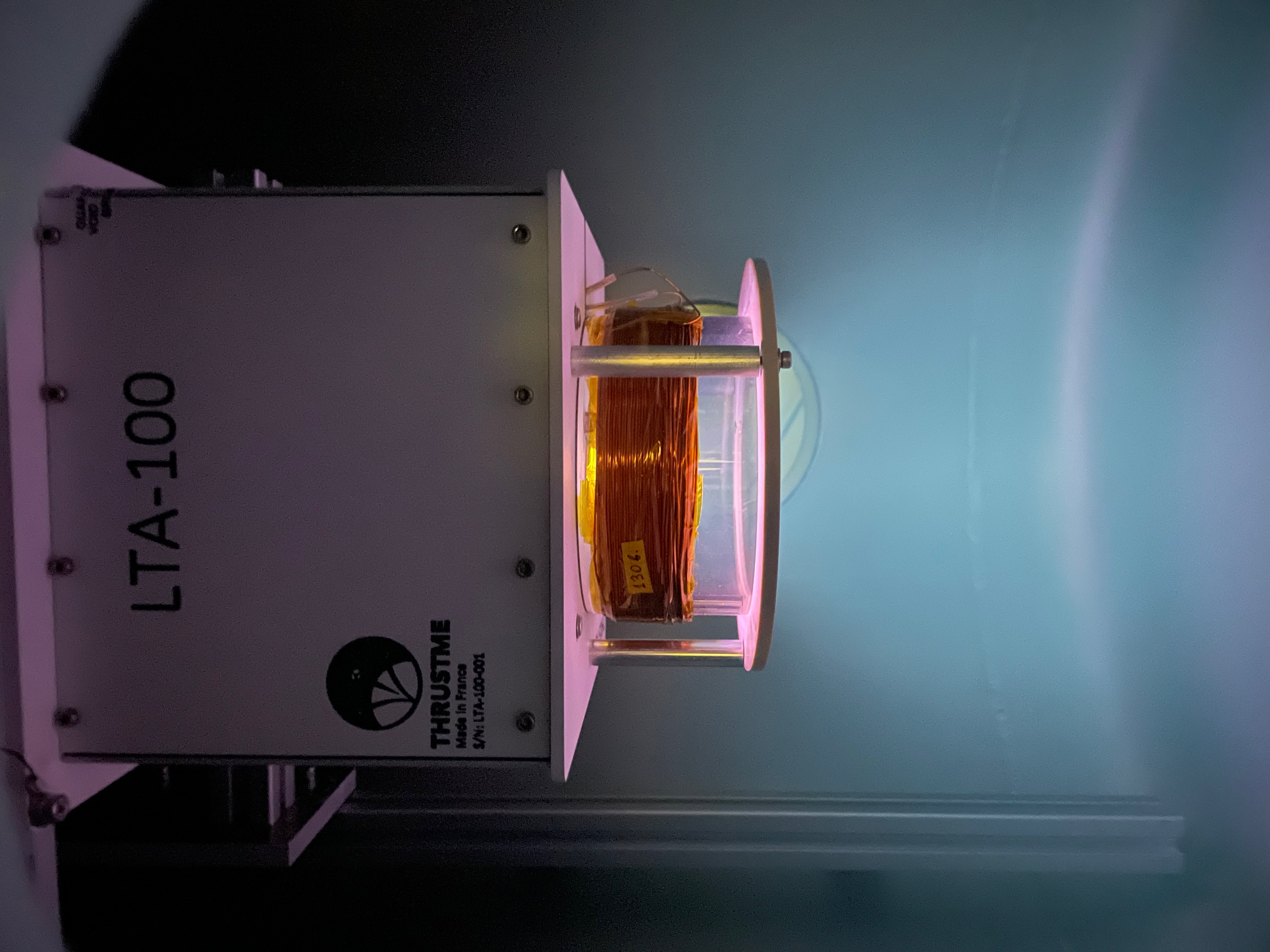

The von Karman Institute facility now includes the LTA100 particle generator developed by ThrustMe, the tool to test how space hardware performs and interacts with the ambient environment during the space flight. “The LTA series is our new line of commercialized plug-and-play products generating the Very Low Earth Orbit (VLEO) and Low Earth Orbit (LEO) environments in the lab, covering both upper atmosphere and ionosphere species. It has never been so simple to change the effective “altitude” of your equipment by simply pressing a button. This has been demonstrated today during the joint acceptance campaign”, says Dmytro Rafalskyi, ThrustMe’s CTO. “The device offers a broad range of operation parameters and can run using various gases and their mixtures. Bringing space to Earth has never been so easy.”

“The success of the acceptance campaign, together with ThrustMe, the von Karman Institute, and ESA experts, demonstrates the flow generator capabilities, and we are eager to further use it in our research work here at the VKI”, said Peter Grognard, VKI’s Managing Director. “VKI is currently expanding the scientific research activities related to space and the DRAG-ON will be an essential facility within our experimental infrastructure”.

About ThrustMe:

ThrustMe is the go-to provider of high-performing in-orbit space propulsion and space hardware testing solutions for customers across the globe. It offers a portfolio of disruptive, deeply integrated and smart in-orbit space propulsion solutions designed for the new industrialised constellation space era. The company made the world’s first demonstration of an iodine-fueled electric propulsion system in space - an achievement the space industry has tried to reach for over 60 years. Now ThrustMe is delivering propulsion systems to major satellite constellations and is offering support from ground testing to in-orbit manoeuvring strategies.

About VKI:

The Institute is an international education and research center that is at the leading edge of fluid dynamics in aeronautics and aerospace, turbomachinery and propulsion, as well as environmental and industrial processes. Today, more than ever, VKI focuses on the study of complex dynamic flows. It is one of the few places in the world where not only numerical simulations, but also extensive experimental research is carried out.

In addition to further expanding the VKI's unique traditional skills and expertise in hypersonic fluid dynamics, the Institute is focusing on several strategic research areas in the coming years, primarily:

• The study and design, of a new generation of very quiet and efficient, low or zero CO2 aircraft engines, including those powered by hydrogen;

• Anticipating the growth of commercial space travel, designing small satellites that can return to Earth;

• The deep and accelerated transition to CO2-neutral energy production, through research activities into hydrogen and wind energy production;

• Extensive decarbonisation of the chemical industry, partly by applying the knowledge of turbomachinery acquired over decades; and

• The study of liquid metals for complex industrial applications